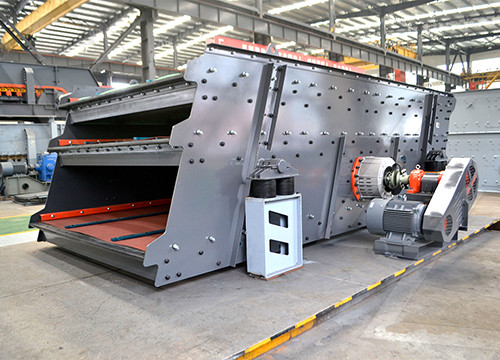

peat vibrating feeder

New tools for particle shape analysis of substrate components ...

fiber, pine bark, and white peat, respectively, were indeed removed by sieving prior to CPA2 measurements. Combining results from both devices indicated that coco fiber presented the widest PSD (with significant parts of smaller and larger particles than the other materials), whereas peat, wood fiber and pine bark showed a narrower PSD (Figure 3).

get price

Structure Optimization of Vibrating Feeder Based on Inertia ...">Structure Optimization of Vibrating Feeder Based on Inertia ...

Reliability is a key factor in the design and manufacture of vibrating feeders. In this paper, a method considering materials force was proposed to optimize the structure of the vibrating feeder. Discrete Element Method (DEM) was used to couple the materials force and the excitation force based on the phase characteristics of the vibrating feeder, and Finite Element Method (FEM) was used to ...

get price

Draft - University of Toronto">Draft - University of Toronto

Linear vibrating feeders are major components of automatic production lines and have a wide range of applications in the medical and military fields, and in the manufacturing of precision instruments. Conventional linear vibratory feeders are classified into electromagnetic and piezoelectric varieties, Maul G P (2005) and Zhan

get price

Influence of natural organic matter in porous media on fine ...

Jun 15, 2018 · To determine the grain size distribution, about 30 mg dry peat moss sample was poured into a vibrating feeder to mix with nanopure water, and the sample was automatically diluted before being analyzed with a laser scattering particle size distribution analyzer (LA-950, Horiba Scientific).

get price

Feeders and Vibrating Conveyors - Springer">Feeders and Vibrating Conveyors - Springer

A belt feeder can be used under certain conditions, if the speed of the belt does not exceed 25-30 fpm. At 40 fpm, the belt may pull out under the load. If greater capacity is required, it is best to widen the feeder and not to increase the speed. 7.3.1 Material Handled The feeder will handle material weighing up to 100

get price

Premier Tech Systems and Automation - DirectIndustry">E series - Premier Tech Systems and Automation - DirectIndustry

Gravity-Vibratory Feeder The E55GV Gravity-Vibratory Feeder is designed to handle free-flowing and semi-free-flowing products. The filling process is performed in two steps. The main feed and product cut-off are achieved by a pneumatically 1 operated radial gate then, a small vibratory feeder provides slow feed to finalize the filling cycle and ...

get price

Vibrating Screens">BIVITEC® - Industrial Disc and Vibrating Screens

Conventional vibrating screens and trommels are very limited when screening materials that cause build-up, which results in clogging or blinding of the screen openings. BIVITEC® dual-vibratory screening process eliminates clogging and blinding of the screen openings to save downtime and increase productivity. Applications once judged impossible

get price

Unbalanced Motor Driven Feeder">ELEKTROMAG-JOEST | Unbalanced Motor Driven Feeder

The Electromagnetic Vibrating feeders are used for precise feeding and the Unbalance Motors and Unbalance Exciter Driven Vibrating feeders are used for discharge of Bulk material at fixed feed rates. Compared to other conveying means, Vibratory feeders are low in energy consumption. Vibratory feeders are available in open trough and tubular ...

get price

Design and characteristic analysis of vibration feeding ...

Dec 18, 2020 · The vibratory feeder is a forced vibrating system mostly used in industries to feed material from hoppers, bins, silos and storage piles to belt conveyors. It is used to control the feed rate of ...

get price

Bagging scale | Net Weigh Scale - PT Chronos">Bagging scale | Net Weigh Scale - PT Chronos

WSN-3000 & WSN-4000 Series w/Gravity-Vibratory Feeders. FEATURES. Production rate: up to 17 BPM; Product applications: bird seeds, corn seeds, pet food, soy beans, etc. Very high accuracy; No mechanical adjustment for product changeovers (with automatic feeder adjustment option) Contact parts in SS304; High hygienic standards; OPTIONS

get price

Your Hard Rock? | Fote Machinery">Which Crusher Is Suitable for Your Hard Rock? | Fote Machinery

Feb 15, 2023 · 1 Coarse crushing and fine crushing: Granite is evenly sent to a jaw crusher through a vibrating feeder for coarse crushing, then sent to an impact crusher or cone crusher through a belt conveyor for fine crushing; 2 Fine crushing and shaping: The materials are screened by a vibrating screen, then sent to a sand maker for fine crushing and ...

get price

Kolberg 271B Hydraulic Screening Plant - AZCE

BELT FEEDER: Heavy-duty g 6" (289m) long roller bet destgn with variab e 'peed hydraulic drive for precise material metering, SHREDDER CAPABILITIES: THE SHREDDER: A 'Tine" type shredder is inc Uded and designed for use in top soil and related applications. SHREDDER HOUSING: y Slides and "Closed" inspection and operation,

get price

Vibrating Grizzly Feeder - IJCRT">Finite Element Analysis of Vibrating Grizzly Feeder - IJCRT

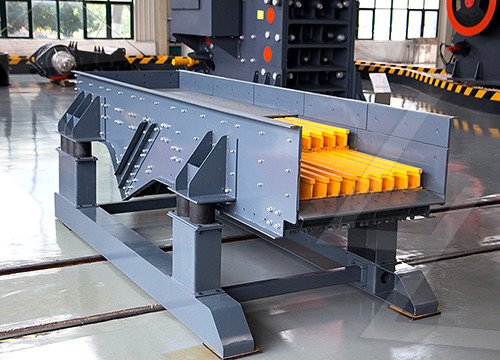

Vibrating Grizzly Feeder works on the phenomena of Vibration. Here vibration means “to move back and forth rapidly.” On a vibratory feeder, material is “thrown” up and forward so that it drops to the surface at a point further down the tray. This is the feeder’s amplitude. The number of times per minute that it repeats is the frequency.

get price

Installation, Operation and Maintenance Instructions - Eriez">Installation, Operation and Maintenance Instructions - Eriez

Vibratory Feeders: Hopper Transition And Installation Guide 5 The capacity of a vibratory feeder is given by: General flow velocities (v) are Eriez “B” model electromagnetic feeders with tray at 10° downslope = 35 ft/minute. Eriez HVF Mechanical feeders at 10° downslope = 50 ft/minute. Reduce “FR” by 2% for

get price

VIBRATING FEEDER - 911 Metallurgist">VIBRATING FEEDER - 911 Metallurgist

May 8, 2021 · The vibratory feeders can resist flooding (liquid-like flow) and are available for capacity ranges from ounces to tons per hour. Electric Vibrating Feeder The Electric Vibratory Feeder is a vibrator that provides an extremely efficient, simple and economical solution to the problem of making the most stubborn material flow freely.

get price

Feeder Vibrators | McMaster-Carr">Feeder Vibrators | McMaster-Carr

They have a built-in vibrator that shakes material to stimulate flow through the trough. They're often used to feed material in mixing or packaging operations. All require a solenoid valve (sold separately). Vibrating feeders with a 304 stainless steel trough are often used in wet and corrosive conditions. For technical drawings and 3-D models ...

get price

Vibrating feeder | PPT - SlideShare">Vibrating feeder | PPT - SlideShare

Feb 11, 2015 · 2. 1.INTRODUCTION A vibrating feeder is a feeder/material conveying equipment consisting of a pan or trough to which a vibrating motion is imparted so that the material is impelled in a definite, controlled flow. Normally, it is positioned under the opening in the bottom of a bin or below an emergency reclaim hopper in a stockpile Generally its use should be avoided where the material is of ...

get price

Weighing And Bagging">Eifers::Weighing And Bagging

General Description: Application: Weighing and counting of Rice bags, Cement bags, carton boxes and all sorts of packaged items in carton and bags. Weighing Range: 50g to 80 kg. Weighing Speed: 3-5 seconds per bag or carton of 60 kg – Accuracy 20g to 50g based on the bags/cartons and feeding method. 70 boxes per minute for 50 g packets ...

get price

vibrating bin feeders Design feeder machine VF ...">BULKMATIC vibrating bin feeders Design feeder machine VF ...

Vibrating Feeders are available as a tube or trough type and rely on two robust vibrator motors to generate the oscillating motion of the feeder. The feeders can either be foot mounted or suspended. The eccentric weight settings on the motors are adjustable to fine tune the required feed rate. For abrasive materials the base of the infeed tube ...

get price

Vibrating Grizzly Feeder | ">Vibrating Grizzly Feeder |

We offer various types of Vibrating Grizzly Feeders, which can be equipped with grizzly bars or grizzly fingers for sticky and difficult-to-screen feed materials. Our grizzly bars are made of highly wear resistant steel and offer maximum lifetime of the screen decks and can be arranged in single, double, triple and even quadruple stepped options subject to duty requirements.

get price

Premier Tech Systems and Automation - DirectIndustry">E series - Premier Tech Systems and Automation - DirectIndustry

Gravity-Vibratory Feeder The E55GV Gravity-Vibratory Feeder is designed to handle free-flowing and semi-free-flowing products. The filling process is performed in two steps. The main feed and product cut-off are achieved by a pneumatically 1 operated radial gate then, a small vibratory feeder provides slow feed to finalize the filling cycle and ...

get price

Vibrating Screens">BIVITEC® - Industrial Disc and Vibrating Screens

Conventional vibrating screens and trommels are very limited when screening materials that cause build-up, which results in clogging or blinding of the screen openings. BIVITEC® dual-vibratory screening process eliminates clogging and blinding of the screen openings to save downtime and increase productivity. Applications once judged impossible

get price

Unbalanced Motor Driven Feeder">ELEKTROMAG-JOEST | Unbalanced Motor Driven Feeder

The Electromagnetic Vibrating feeders are used for precise feeding and the Unbalance Motors and Unbalance Exciter Driven Vibrating feeders are used for discharge of Bulk material at fixed feed rates. Compared to other conveying means, Vibratory feeders are low in energy consumption. Vibratory feeders are available in open trough and tubular ...

get price

Design and characteristic analysis of vibration feeding ...

Dec 18, 2020 · The vibratory feeder is a forced vibrating system mostly used in industries to feed material from hoppers, bins, silos and storage piles to belt conveyors. It is used to control the feed rate of ...

get price

Bagging scale | Net Weigh Scale - PT Chronos">Bagging scale | Net Weigh Scale - PT Chronos

WSN-3000 & WSN-4000 Series w/Gravity-Vibratory Feeders. FEATURES. Production rate: up to 17 BPM; Product applications: bird seeds, corn seeds, pet food, soy beans, etc. Very high accuracy; No mechanical adjustment for product changeovers (with automatic feeder adjustment option) Contact parts in SS304; High hygienic standards; OPTIONS

get price- معدات ثقيله بابها عرجاء

- كسارة كام رافعة

- سوق شـاحنـات ومعدات ثقيلة

- اسماء المعلامات الناقلات بجازان حي الدمنه

- حصاة أسعار المعدات سحق

- تلحيم الحديد

- حفارات هيدروليكية أسعار الإيجارات كسارة الصخور

- كسارة الفك صور

- شركات كسارات صينيه متنقله

- نشيد طاحونة روبي

- ماكنة تصنيع وتغليف الترامادول

- شركة مايت الإطاليةالمتخصصة فى صناعة العدات الثقيلة وحفر الشوارع والأ

- الاوراق المطلوبة لدخول المعدات الثقيلة