high quality rock crusher crushing plant primary jaw crusher

Rock Crushers and Crushing Plants: A Complete ...">Gold Mining Rock Crushers and Crushing Plants: A Complete ...

Feb 22, 2023 · However, they can be more expensive to purchase and maintain compared to jaw and cone crushers. Benefits of Using Quality Rock Crushers for Gold Mining. Using quality rock crushers in your gold mining operation can bring a range of benefits, including increased efficiency and reduced operating costs. By investing in quality equipment, you can:

get price

Jaw Crushers Price - Made-in-China.com">Jaw Crushers Price - Made-in-China.com

New System ISO CE Approved Complete Quarry Crushing Plants, Granite Limestone Gravel Jaw Crusher, Factory Price Aggregate Rock Mobile Stone Crusher Plant US$ 45600-45800 / Piece 1 Piece (MOQ)

get price

Jaw Crusher">McLanahan | How To Size A Jaw Crusher

Jun 23, 2023 · A Jaw Crusher is sized so that the maximum feed size is 80% of the gape and width openings. The gape is the measurement between the two jaw dies, while the width is the measurement between the two side plates. For example, if the maximum feed size is 29”x49”, the crusher gape would be 32” and the width would be 54”.

get price

What Is an Impact Crusher and What Can It Do for You?">What Is an Impact Crusher and What Can It Do for You?

Jan 10, 2021 · An impact crusher, or impactor, is one of several types of crushing machines, including jaw crushers, hammermills, and cone crushers, that is manufactured for the purpose of processing raw materials, like concrete or asphalt, among many others, to reduce them in size. Used in a wide variety of applications, including aggregate crushing, asphalt ...

get price

surface: Setting up an underground primary jaw crusher">Below the surface: Setting up an underground primary jaw crusher

Apr 1, 2014 · Jaw crushers are the most common solution in underground applications when the throughput is below 1000 tonnes per hour, depending somewhat on the scalping solutions. Above 1000 tph, primary gyratory crushers are an option. After the throughput reaches 2000 tph, jaw crushers are very rare, with the exception of a parallel plant layout.

get price

Primary Crusher? - machinerypartner.com">What is a Primary Crusher? - machinerypartner.com

A primary crusher breaks up large pieces of rock or concrete from the blasting or excavation process and turns them into smaller, more manageable chunks. This is the first step in the crushing process. The smaller pieces can then either be pre-screened or fed directly into a secondary impact or cone crusher.

get price

Primary Crushing, Secondary ... - AGICO">The Complete Guide to Primary Crushing, Secondary ... - AGICO

Feb 28, 2023 · Primary, secondary, and tertiary crushing are three stages in the comminution process that break down large rocks into smaller pieces of varying sizes. Each stage uses different types of crushers and has distinct advantages and disadvantages. This article provides a comprehensive guide to primary, secondary, and tertiary crushing.

get price

Crusher - Eastman Rock Crusher">Mobile Crusher - Eastman Rock Crusher

Option 1. High-hardness rock crushing ($100,000-180,000) Main equipment: jaw crusher, HP hydraulic cone crusher, 2YK1548 vibrating screen Applicable materials: iron ore, granite, basalt, quartz, etc. Production capacity: 80-200t / h Feeding granularity: ≤500mm The discharge can meet the requirements: 10-30mm; Option 2.

get price

Jaw Crusher - Mineral Processing">Jaw Crusher - Mineral Processing

Jaw crusher is one of the most commonly used primary crushers in the ore processing plant, with a capacity range of 1-1000tph. There are two types of feeding opening designs, rectangular and square shape. JXSC also provides multiple models or customized (fixed or mobile type)jaw crushers to meet various processing needs of users.

get price

Crushing Limestone | Impact & Jaw Crushers | RUBBLE MASTER">Crushing Limestone | Impact & Jaw Crushers | RUBBLE MASTER

Since 1991, RUBBLE MASTER has brought numerous innovations to the market. We’re crushing & screening experts and work closely with contractors and aggregate producers world-wide. Mobile jaw & impact crushers for crushing limestone into high-quality aggregates. Turn your limestone into cash with equipment that works as hard as you!

get price

Jaw Crushers - Astec">Jaw Crushers - Astec

Available in a variety of sizes and configurations, the Hydra-Jaw® crusher, Pioneer® jaw crusher and Iron Giant jaw crushers deliver high-capacity crushing and reliable performance for increased operational productivity and profitability. Our diverse line of industry-leading jaw crushers offers producers the latest in jaw crushing technology ...

get price

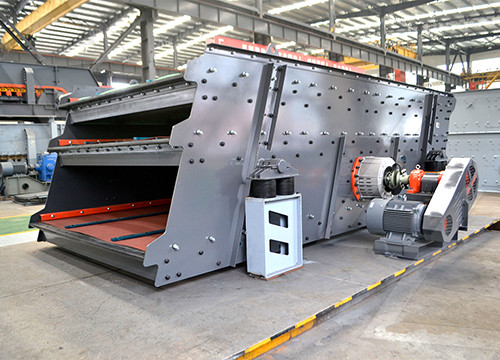

Vibrating Screen - Eastman Rock Crusher">Vibrating Screen - Eastman Rock Crusher

1-1120t/h. Output size. 10-350mm. Vibrating screen is the most popular screening equipment widely used in the crushing and screening plant. It does circular trajectory, so also known as the circular vibratory screen. rectangular single-, double-, and multi-layer, high-efficiency new screening equipment. Screen Layer 1-4 layer.

get price

crushers for distinctive needs - Metso">Different types of crushers for distinctive needs - Metso

Dec 17, 2020 · Primary crushing is for the robust. The very first crushers invented were jaw crushers, which are built to reduce the size of large materials and operate with high volume in primary crushing. Their main purpose is to reduce the material to a small enough size that it can be transported to the next crushing stage by conveyors. Jaw crushers can ...

get price

crushing & screening plants">Metso NW Series™ Portable crushing & screening plants

applications. NW Series plants can be operated as independent units or as a two- or three-stage crushing application: from primary to secondary, tertiary and fine crushing. NW Series portable plants are built around the proven ® and

get price

Crushing it: A Comprehensive Guide to Stone Crusher Plants">Crushing it: A Comprehensive Guide to Stone Crusher Plants

Feb 28, 2023 · Stone Crusher Plant Workflow. The workflow of a stone crusher plant involves several steps, including the feeding, crushing, screening, and conveying of materials. The materials are fed into the primary crusher by the vibrating feeder, where they are crushed into smaller pieces. The smaller pieces are then sent to the vibrating screen for ...

get price

Jaw Crusher - Turn Waste Concrete Into Sand">Jaw Crusher - Turn Waste Concrete Into Sand

Our crushers adopt deep crushing cavities, so the feeding rate and crushing efficiency can be greatly improved. It is also energy-saving. Compared with other crushers, it can save more than 50% energy. Jaw crushing plant has advanced technology, long service life, reliable working condition, easy maintenance, and other advantages. Uses of Jaw ...

get price

Jaw Crusher - Jaw Crusher Types - Jaw Crusher Prices - Fabo">Jaw Crusher - Jaw Crusher Types - Jaw Crusher Prices - Fabo

Jaw crusher is one of the most important equipment of the concaveplants. It can be designed in two different ways, mobile and stationary. This type of crusher breaks large stones in crushing and screening plants, bringing them to smaller sizes. Thus, aggregate is obtained from stones. Jaw crusher are very powerful crushers that can be used in ...

get price

Crusher, Crusher Manufacturers, Suppliers, Price | Made ...">China Crusher, Crusher Manufacturers, Suppliers, Price | Made ...

Mobile Stone Iron Gold Ore Rock Mining 100-150 Tph Jaw Crusher Manufacturers Price Portable Granite Crushing Machine Plant for Sale US$ 8960-29646 / Set 1 Set (MOQ)

get price

High-capacity crusher, High-capacity crushing plant - All ...">High-capacity crusher, High-capacity crushing plant - All ...

Capacity: 50 t/h - 1,200 t/h. Motor power: 200 kW - 1,800 kW. Opening height: 600 mm - 1,900 mm. A wide range of crushing and screening plant with best in class solutions, highest efficiency and lowest investment costs. Complete solutions from jaw crusher, cone crusher, vertical ...

get price

surface: Setting up an underground primary jaw crusher">Below the surface: Setting up an underground primary jaw crusher

Apr 1, 2014 · Jaw crushers are the most common solution in underground applications when the throughput is below 1000 tonnes per hour, depending somewhat on the scalping solutions. Above 1000 tph, primary gyratory crushers are an option. After the throughput reaches 2000 tph, jaw crushers are very rare, with the exception of a parallel plant layout.

get price

Primary Crusher? - machinerypartner.com">What is a Primary Crusher? - machinerypartner.com

A primary crusher breaks up large pieces of rock or concrete from the blasting or excavation process and turns them into smaller, more manageable chunks. This is the first step in the crushing process. The smaller pieces can then either be pre-screened or fed directly into a secondary impact or cone crusher.

get price

Primary Crushing, Secondary ... - AGICO">The Complete Guide to Primary Crushing, Secondary ... - AGICO

Feb 28, 2023 · Primary, secondary, and tertiary crushing are three stages in the comminution process that break down large rocks into smaller pieces of varying sizes. Each stage uses different types of crushers and has distinct advantages and disadvantages. This article provides a comprehensive guide to primary, secondary, and tertiary crushing.

get price

Crusher - Eastman Rock Crusher">Mobile Crusher - Eastman Rock Crusher

Option 1. High-hardness rock crushing ($100,000-180,000) Main equipment: jaw crusher, HP hydraulic cone crusher, 2YK1548 vibrating screen Applicable materials: iron ore, granite, basalt, quartz, etc. Production capacity: 80-200t / h Feeding granularity: ≤500mm The discharge can meet the requirements: 10-30mm; Option 2.

get price

Jaw Crusher - Mineral Processing">Jaw Crusher - Mineral Processing

Jaw crusher is one of the most commonly used primary crushers in the ore processing plant, with a capacity range of 1-1000tph. There are two types of feeding opening designs, rectangular and square shape. JXSC also provides multiple models or customized (fixed or mobile type)jaw crushers to meet various processing needs of users.

get price- معدات ثقيله بابها عرجاء

- كسارة كام رافعة

- سوق شـاحنـات ومعدات ثقيلة

- اسماء المعلامات الناقلات بجازان حي الدمنه

- حصاة أسعار المعدات سحق

- تلحيم الحديد

- حفارات هيدروليكية أسعار الإيجارات كسارة الصخور

- كسارة الفك صور

- شركات كسارات صينيه متنقله

- نشيد طاحونة روبي

- ماكنة تصنيع وتغليف الترامادول

- شركة مايت الإطاليةالمتخصصة فى صناعة العدات الثقيلة وحفر الشوارع والأ

- الاوراق المطلوبة لدخول المعدات الثقيلة